In the fast-evolving electronics industry, small components play a significant role in ensuring the safety, durability, and performance of electrical systems. One such unsung hero is the eyelet. These tiny cylindrical components are used extensively across electrical assemblies to provide mechanical strength, electrical conductivity, and insulation.

Let’s dive into the key functions and applications of eyelets in electrical and electronics systems:

1. Circuit Board Assembly

Eyelets are used in printed circuit boards (PCBs) to reinforce vias and through-holes. These holes often connect different layers of a multi-layer board, and eyelets ensure structural integrity while maintaining conductive paths. They also make soldering easier and more reliable. Companies like Sweetone Industries specialize in manufacturing precision eyelets for such critical PCB applications.

2. Cable Reinforcement

When electrical cables pass through metal enclosures or sharp-edged panels, eyelets act as reinforcement sleeves. They protect the cable insulation from wear and tear due to friction, extending the cable’s life and maintaining electrical safety.

3. Component Mounting

In some assemblies, eyelets are used to securely mount electrical components onto substrates or panels. This dual-purpose application not only fastens components but also serves as a conductor, allowing electrical continuity.

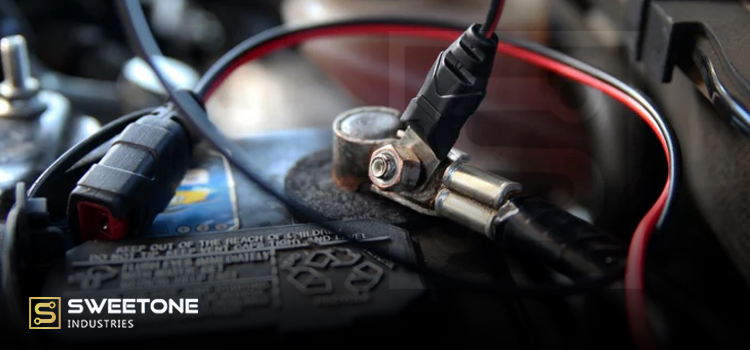

4. Grounding Applications

Reliable grounding is critical to preventing electric shock and minimizing electromagnetic interference. Metallic eyelets serve as effective grounding points, ensuring a secure connection to earth ground in various devices and systems.

5. Electrical Insulation

Some eyelets, made from non-conductive materials, are designed to insulate components from surrounding conductive surfaces. These are crucial in preventing short circuits, especially in compact or high-voltage circuits.

6. Shielding and EMI/RFI Protection

Eyelets also contribute to the shielding of sensitive components from electromagnetic interference (EMI) and radio frequency interference (RFI). This is particularly important in communication devices, medical electronics, and automotive circuits.

7. Repair and Maintenance

In the maintenance of electrical equipment, eyelets are often used to repair worn-out connections or replace damaged vias. Their easy-to-install design makes them ideal for retrofit or repair tasks in legacy equipment. Electrical & Metal Parts India provides durable solutions for such high-precision repair applications.

8. High Current Applications

For circuits that handle large currents, heavy-duty eyelets made of copper, brass, or other conductive metals are used. These eyelets are capable of managing high electrical loads without overheating or degrading.

Conclusion

Whether in a complex circuit board or a basic electrical panel, eyelets provide reliability, conductivity, and mechanical strength that are critical to modern electronics. As the demand for more compact and efficient systems grows, so does the importance of choosing the right eyelets for each application.